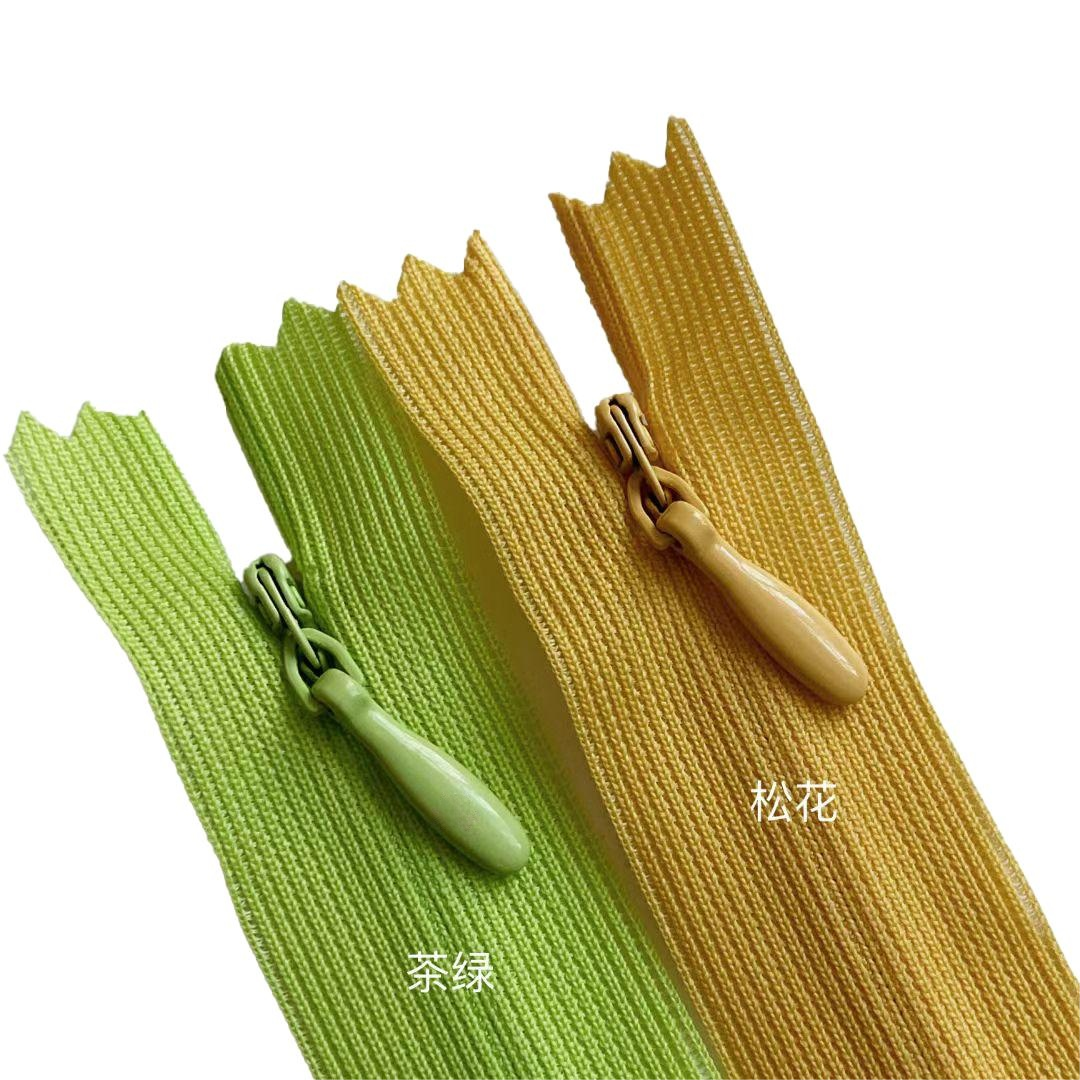

#5 coil zipper silver teeth

Electroplated tooth zippers primarily use vacuum coating technology to apply a shiny metallic film onto the zipper teeth, achieving an eye-catching glossy effect. Features: Nylon zipper #3, #4, #5, #7, #8, #10 Applications: The high-gloss texture enhances the fashion sense and individuality of garments, making it commonly used in sportswear and luggage.

keyword:

Category:

Product

Email:

Details

Components and Manufacturing Processes of Zippers

Slider

The slider is the main component of a zipper. In addition to its basic functionality, it has become one of the decorative highlights on garments. The basic types of sliders include auto-lock sliders, non-lock sliders, pin-lock sliders, spring-loaded sliders, rotating sliders, European-style sliders, rear-action sliders, and invisible sliders, each suited for different product requirements. Sliders are primarily made of zinc alloy, copper, or polyoxymethylene (POM).

Slider Surface Treatment

Common surface finishes for sliders include barrel spray painting, hanging spray painting, barrel plating, and hanging plating. Hanging spray painting and hanging plating provide a smoother and more polished surface compared to barrel plating and spray painting.

Chain Tape

The chain tape is the main body of the zipper. Based on material and manufacturing techniques, zippers can be divided into three major categories: nylon zippers, resin zippers, and metal zippers. Nylon zippers are soft and lightweight, resin zippers offer better decorative appeal, and metal zippers provide a distinct metallic texture and feel. These three types cater to different functional and aesthetic needs in apparel, bags, footwear, and outdoor gear. Chain tapes are primarily made of polyester or cotton yarn.

Chain Tape Processing

Beyond basic dyeing, printing techniques are widely used to apply various patterns and designs onto the tape. Heat-cutting can create lace-like effects, enhancing the zipper's decorative appeal. Lamination allows the integration of reflective or waterproof films, expanding the zipper's applications in specialized products.

Top Stop

The top stop is located at the upper end of the zipper, preventing the slider from detaching and serving as a positioning element. There are two types: non-detachable (mainly used in children's products to prevent accidental ingestion) and replaceable (facilitating slider replacement and garment repair).

Types of Top Stops

Top stops come in various forms, including metal (aluminum or copper) stamped stops, plastic injection-molded stops, and high-frequency heat-pressed polyester stops. Different materials and designs cater to different product needs.

Bottom Stop

The bottom stop is located at the lower end of the zipper, preventing the slider from detaching and serving as a positioning element.

Types of Bottom Stops

Bottom stops are made using similar processes as top stops, including metal stamping (aluminum or copper), plastic injection molding, and high-frequency heat-pressed polyester. Different materials and shapes suit different product requirements.

Zipper Retainer Box

The retainer box is positioned at the bottom of the zipper, enabling the separation and rejoining of the two chain tapes. It is used in open-end and double-open-end zippers.

Types of Retainer Boxes

Retainer boxes are primarily made of two materials: plastic injection-molded boxes and zinc alloy die-cast boxes. Alloy boxes offer better physical durability, while plastic boxes are smoother, safer, and rust-proof. Both types serve different product needs.

Zipper Styles

Zippers come in six basic styles: closed-end, open-end, double-open-end, "O"-type, "X"-type, and "R"-type zippers, each designed for different opening mechanisms and product applications.

-

Closed-End Zipper: Opens from the top to the bottom, with non-separable chain tapes. It consists of one slider and a chain tape, with a top stop at the upper end and a bottom stop at the lower end. Commonly used in handbags and garment pockets.

-

Open-End Zipper: Can be fully opened from top to bottom, allowing the chain tapes to separate. It includes one slider and a chain tape assembly, with a top stop at the upper end and a retainer box at the lower end. Often used in garment plackets, detachable sleeves, trouser cuffs, sofa covers, and mattress covers.

-

Double-Open-End Zipper: Can be opened from both the top and bottom, allowing the chain tapes to separate. It consists of two sliders and a chain tape assembly, with top stops at both ends and retainer boxes in the middle. Used in garment plackets, detachable sleeves, trouser cuffs, sofa covers, and mattress covers.

-

"O"-Type Zipper: Cannot be opened at either end; the slider can slide between the two ends, and the chain tapes are non-separable. It includes two sliders and a chain tape, with bottom stops at both ends. Due to its bidirectional opening feature, it is commonly used in luggage and tents.

-

"X"-Type Zipper: Can be opened at both ends, with the slider sliding between them, while the chain tapes remain non-separable. It consists of two sliders and a chain tape, with top stops at both ends. Used in luggage and tents for bidirectional opening.

-

"R"-Type Zipper: Can be opened at one end, with the slider sliding between the two ends, while the chain tapes remain non-separable. It includes two sliders and a chain tape, with a top stop at one end and a bottom stop at the other. Used in bags and garment pockets.

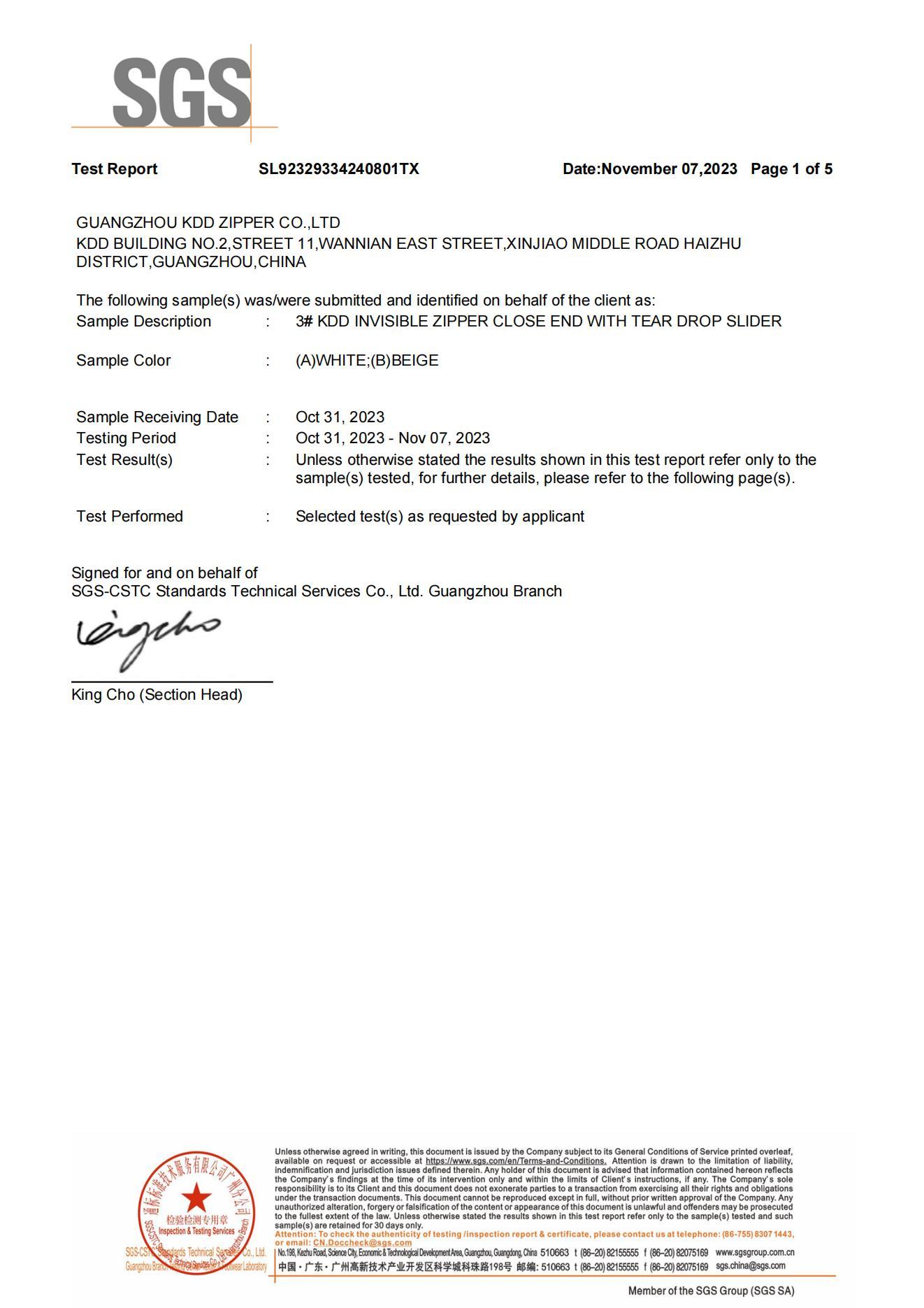

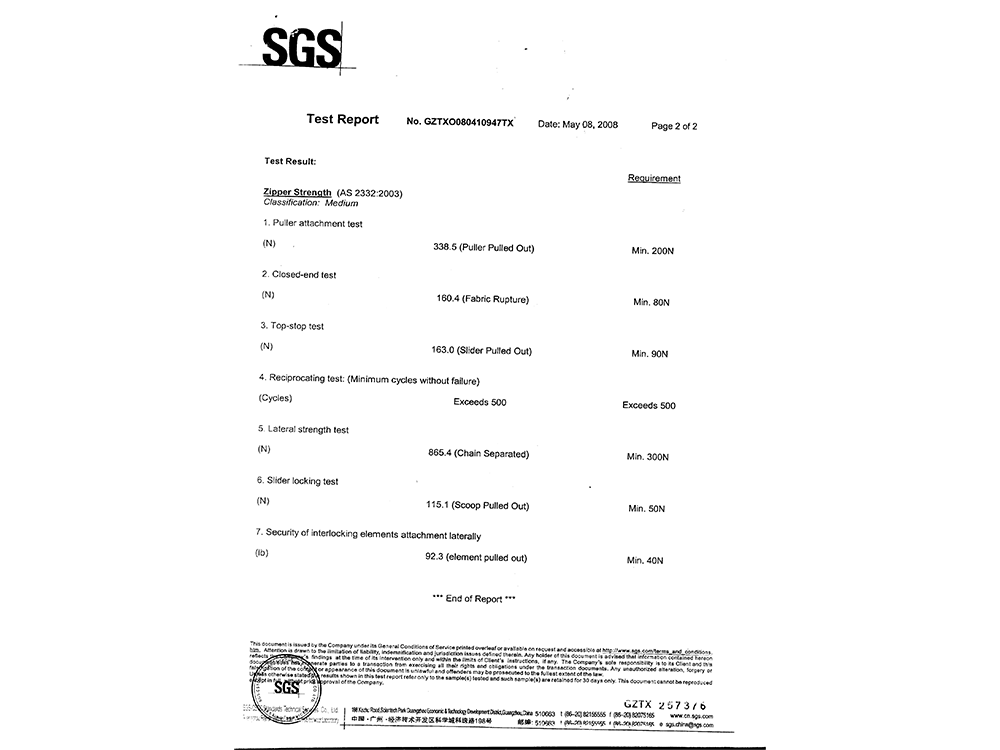

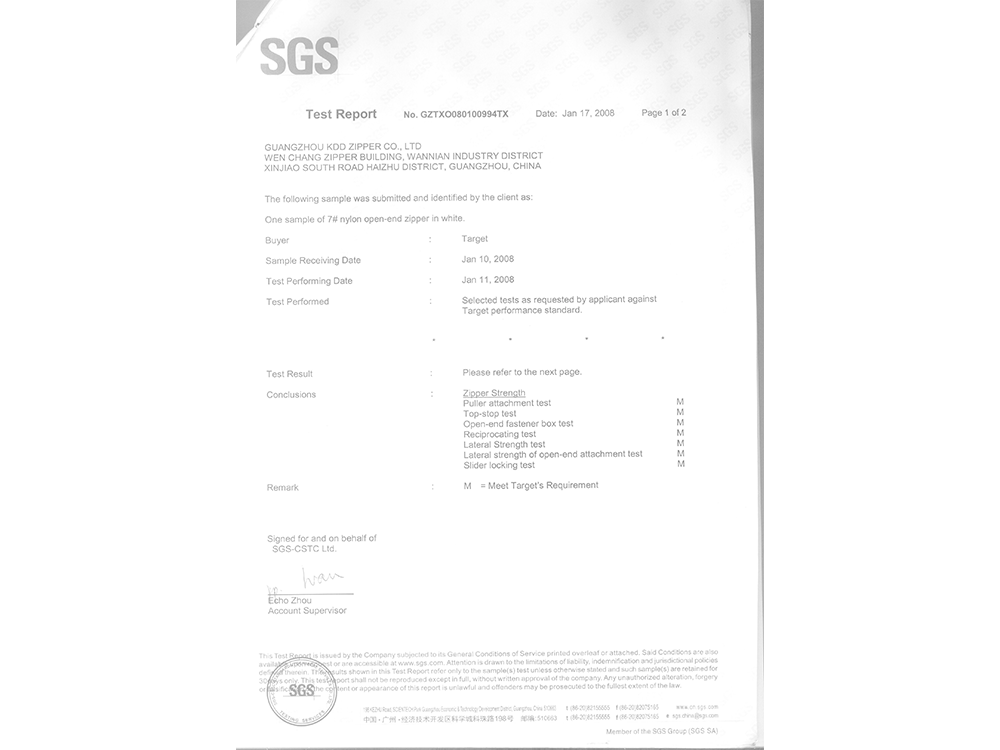

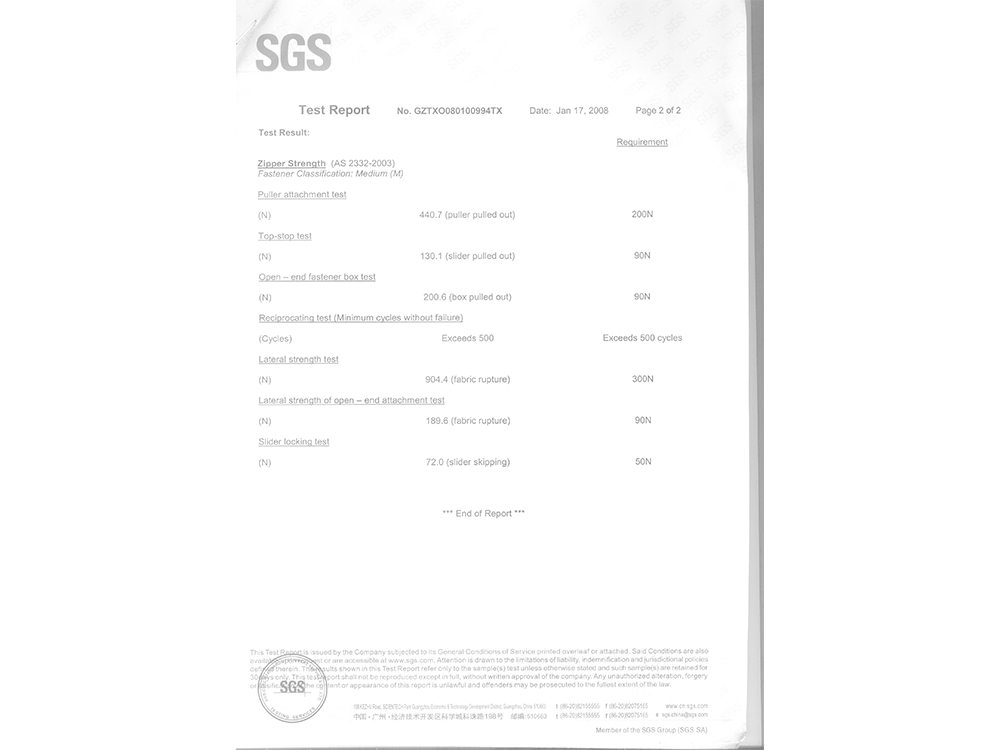

Certificate

Enterprise Strength

FAQ

T/T,Western Union,Paypal,etc..

Spot goods: we can send the goods on the same day you place oder at working time.

Custom products: It usually takes 3-12 days depending on your orders.

Yes, we can provide samples for free,you only need to pay the shipping cost

Any quantity is available

Yes,we can . we are a factory and we welcome to customized order by following your requirements.

Yes, we can develop moulds If you need,we can open mould by following your requirements.

Related products

Inquiry